Intel already has two phases of that goal under its belt with the Intel 7 and Intel 4 nodes, and says it remains on schedule to achieve the other three milestones with Intel 3, 20A, and 18A. The company is clearly aligned on this audacious goal 'Five nodes in four years' is a pervasive mantra repeated by everyone from the executives and marketing leads down to the personnel on the factory floor. Instead, they're part of Intel's rapid expansion as it races to build out both the fab and packaging capacity to satisfy the at-times insatiable demand for semiconductors while working to reach its goal of delivering five new process nodes in four years.

These cranes aren't needed for the day-to-day operation of the plants. Intel's Malaysian campuses are no exception.

Intel has held several tours of its factories in recent times, and an assortment of construction cranes piercing the sky always makes it easy to spot the company's campuses from far away. Intel's ongoing expansion in Penang will soon add the ability to do Foveros packaging in Malaysia. The final process of employing EMIB packaging in the final chip is done in Malaysia. Although those fabs are listed as advanced packaging capable due to their EMIB packaging capabilities, they currently don't do Foveros packaging for Meteor Lake - that step is done first in Rio Rancho, New Mexico. The Malaysian facilities in its Penang and Kulim campuses represent the crown jewels of the company's packaging capabilities. The map in the album above indicates the locations of Intel's different fab operations, including the wafer fabs (blue), advanced packaging facilities (green), and assembly and test facilities (orange), with Malaysia conducting both advanced packaging and assembly and test. In total, the company sells nearly a million processors per day, and it leverages a global network of packaging facilities, including facilities in the US, Malaysia, China (Chengdu), and Vietnam, to accomplish that feat. While this process admittedly isn't as exotic as the magical process of actually fabricating a processor by bending light to our will to etch nanometer-scale features, the technological wizardry involved in chip packaging is also mind-bending, especially given the sheer scale of Intel's operation.

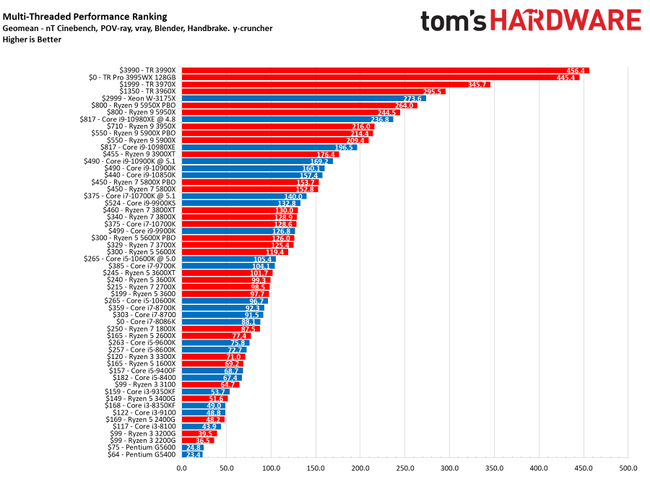

#CPU RANKING PC#

We also have videos of several areas as well.Īt its most basic level, chip packaging is the undertaking of processing a finished wafer, cutting it into separate dies, testing and sorting ( binning) the chips, connecting them to an underlying substrate that often involves complex connections to other dies, and then placing an integrated heat spreader ( IHS) on top to create a fully-functional processor that's ready to head off into distribution channels, then eventually into your PC or other devices. Many of the world's best CPUs are packaged at the facility we visited. Photos of these restricted areas also weren't allowed, but Intel provided us with hundreds of heavily-screened photos so we can give you a peek behind the curtain. We weren't allowed to ask plant personnel questions pertaining to output, yields, or production capacity, or repeat or rephrase any question they refused to answer violations that we were warned would result in being quickly escorted from the premises. That level of secrecy is needed to protect Intel's proprietary tech, but it made note-taking a bit tough, especially given the sheer volume of technical information the company shared once we were inside the buildings. We couldn't bring anything into the production line areas - not even a Fitbit or lip balm - a requirement that security personnel verified with metal detectors before and after we entered the restricted areas. The production capabilities of these facilities and the technology and machines that power them are among some of Intel's most closely guarded secrets.

Until now, these facilities have been shrouded in secrecy, and that veil hung thick over our tour.

#CPU RANKING SERIES#

Intel and TSMC are competing furiously to provide the most advanced packaging technologies available, and Intel's Malaysia facilities play a key role in its efforts as it looks to ramp up its Meteor Lake production, a new series of consumer CPUs that employ groundbreaking production techniques.

0 kommentar(er)

0 kommentar(er)